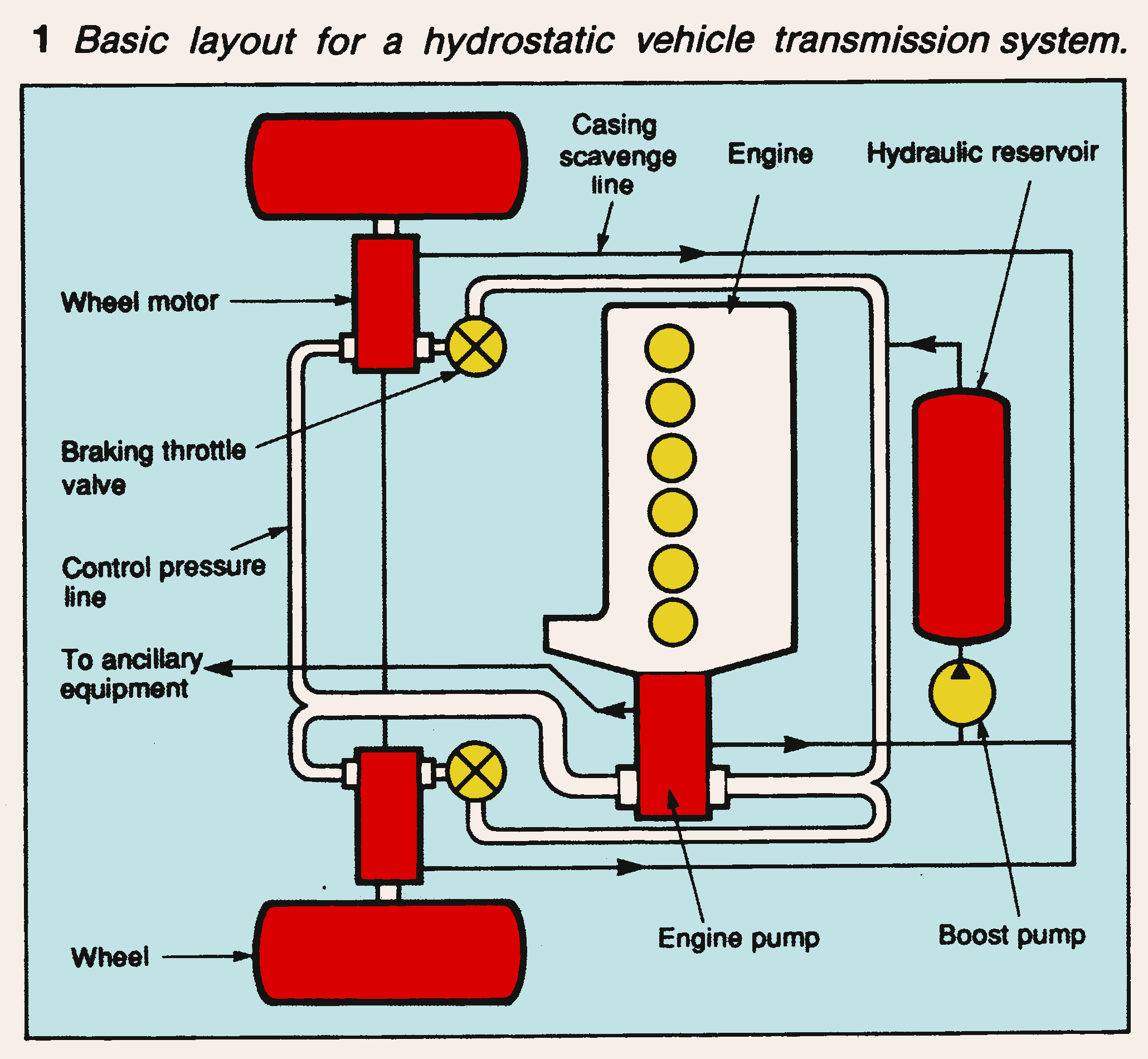

Hydrostatic transmission for road vehicles has low losses at high speeds

For example, an engine might produce its maximum horsepower at 5,500 rpm. The transmission allows the gear ratio between the engine and the drive wheels to change as the car speeds up and slows down. You shift gears so the engine can stay below the redline and near the rpm band of its best performance.

Everything You Should Know About Car Transmission System

Context in source publication. Context 1.. layout of the transmission investigated is shown in Fig. 1. Appropriate ranges for the geometrical and inertial properties of all gear sets are listed.

5 Transmission Problems You Need to Know AAMCO Minnesota

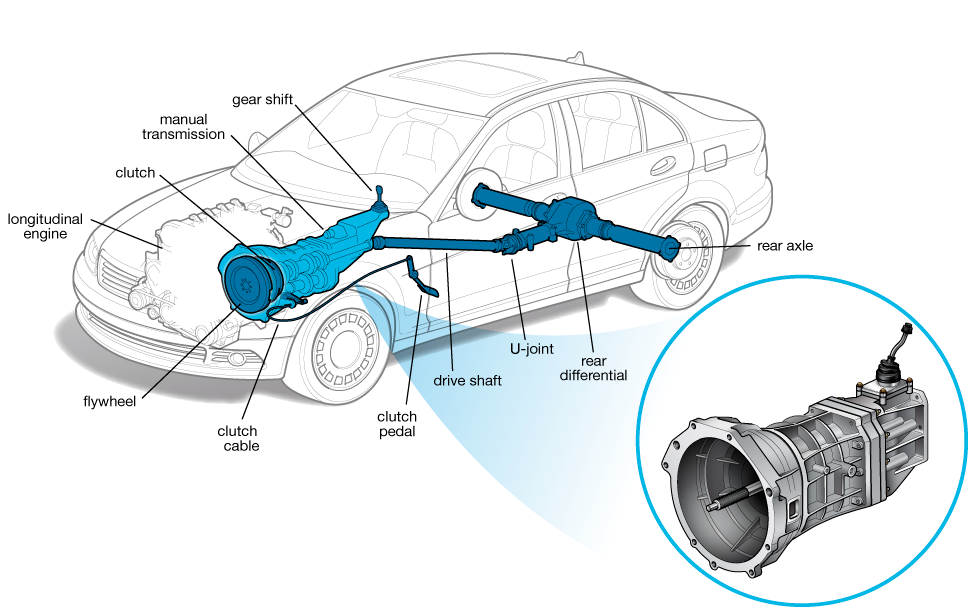

3. Propeller shaft: The third component of the automobile transmission system, which transfers motion from the gearbox end to the differential end. The distance between the two can be large, and therefore, it is a shaft which is thin and long to connect the two. 4.

Manual Transmission

'What is Transmission System?' is a topic of learning that is a part of the 'Automobile Engineering' course that covers Body Structure, Power Unit, Transmiss.

Car and truck transmission service and repairs

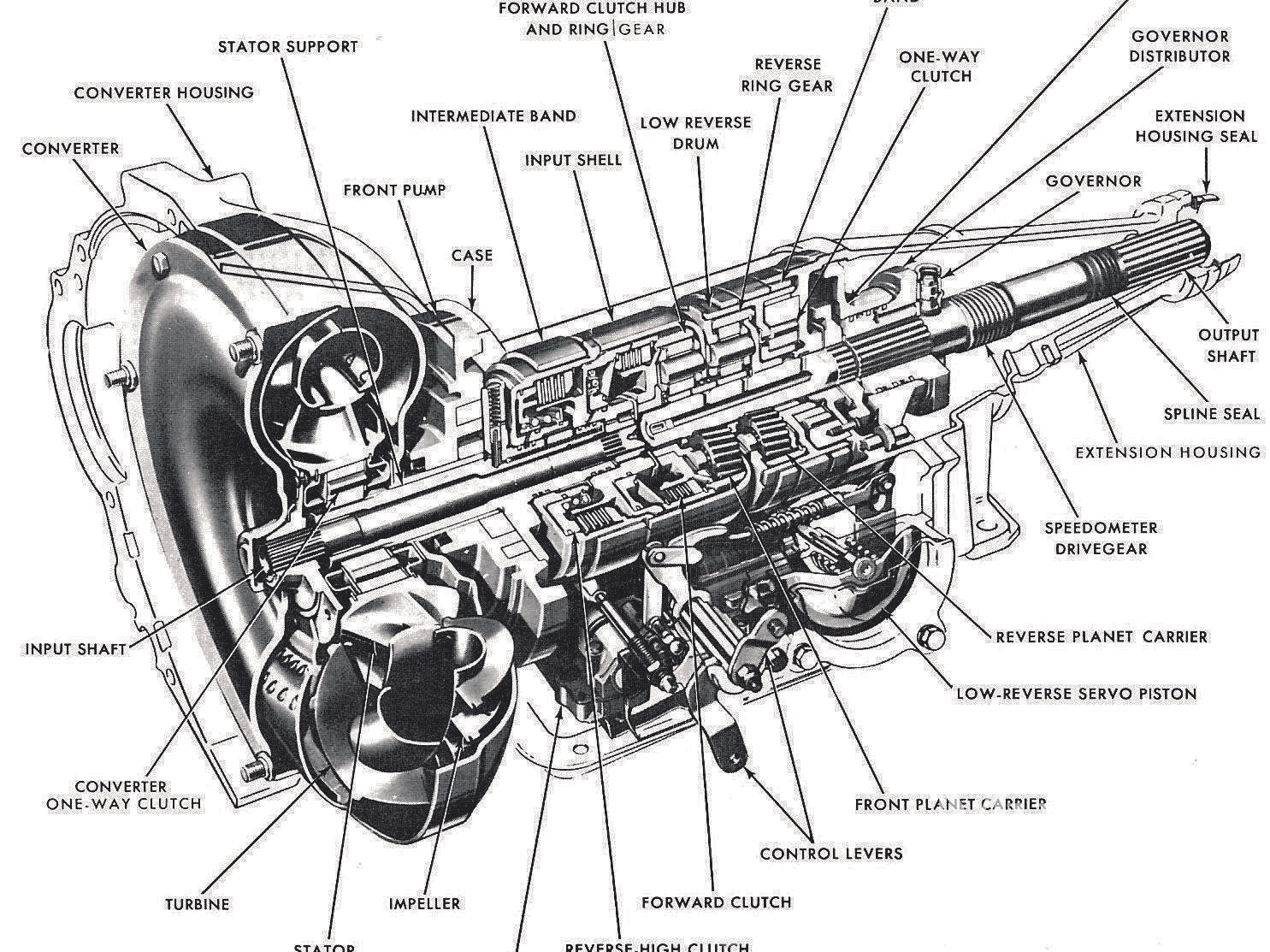

Automatic Transmission Diagram #2 - Planetary Gear Sets. The planetary gearset is located between the engine and wheels, allowing the car to move at different speeds depending on the driver's requirements. We call it an epicyclic gearing system because it uses one or more sun gears and one or more planet gears connected by outside rings or carriers (called planet carriers).

Transmission Repair in Mays Landing, NJ Kneble's Auto Service Center

The design of the transmission system for offshore wind farm cluster is an integrated optimization problem that can be divided into three layers: (1) optimization for the offshore substation

Ferguson FourWheelDrive System Explained The Jensen Museum

The Modern Approach to Transmission System Design and Analysis. Over the last 15 years, there has been significant growth in the number of transmission types as well as their complexity: manual, conventional automatic, dual clutch, automated manual, continuously variable, split power and pure EV transmissions.

design of transmission system YouTube

Manual transmission is the common and popular type of transmission used in vehicles. In this system, the driver must select gears manually by operating the gear stick and clutch. The basic function of the transmission is to control the speed and torque of the vehicle in different driving conditions. Basically, the manual transmission works on.

Design of Transmission Systems ARS Publications

The transmission system is one of the most basic and important parts of a vehicle. You can define it like this, it transfers power from the engine to the wheels.Transmission simply refers to the gearbox, which uses gears and gear trains to provide speed and torque.. It is one of the most complex components of your vehicle consisting of a series of gears (gearbox).

Transmission system and layout of automobile engineering YouTube

Herringbone gear planetary gear transmission system has the advantages of high contact ratio and high bearing capacity and is widely used in various heavy load fields. However, the gear generates a large amount of heat during the meshing transmission, which affects the nonlinear dynamic characteristics of the system. In this paper, the various nonlinear factors are considered, including time.

How to Decide Between Manual and Automatic Transmissions YourMechanic Advice

The Pump. Automatic transmissions have a neat pump, called a gear pump. The pump is usually located in the cover of the transmission. It draws fluid from a sump in the bottom of the transmission and feeds it to the hydraulic system. It also feeds the transmission cooler and the torque converter.

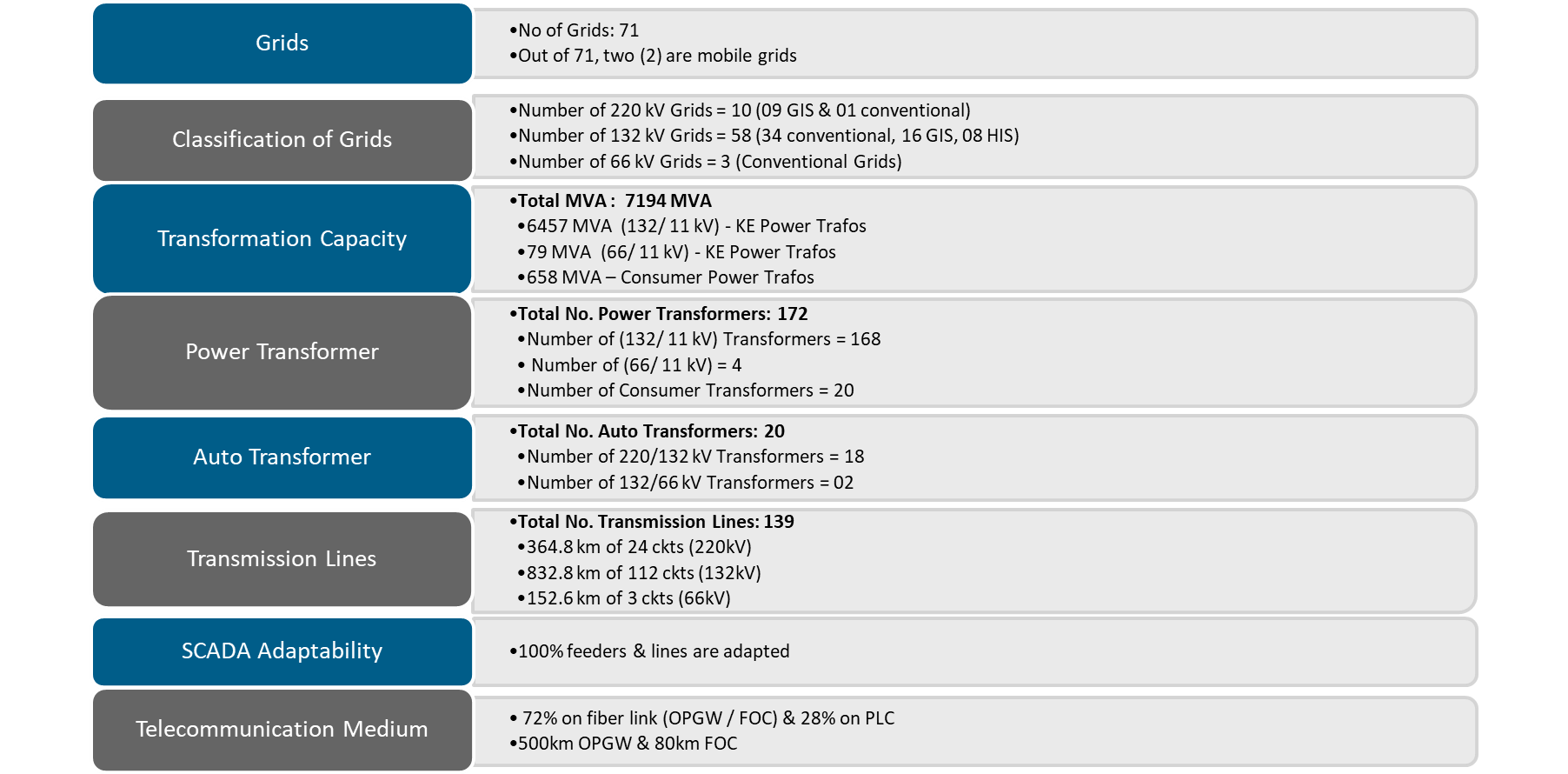

List of 132 Kv Grid Station in Pakistan Meeks Sexagnat

144 6 Vehicle Transmission Systems: Basic Design Principles Fig. 6.4. Drive designs for trucks with one or more powered axles. a 4 x 2; b 4 x 2, underfloor engine; c 4 x 4, all-wheel-drive; d 6 x 2, trailing axle; e 6 x 2, leading axle; f 6 x 4; g 6 x 6, with drive-through to second rear axle; h 6 x 6, second rear axle with direct drive; i 8 x 2, trailing axle; j 8 x 4;

Transmission system ESB Archives

Pyramid-shaped transmission system (TS) of multiarm concentric-tube robots (CTRs) offers advantages of convenient arrangement and collision avoidance of the actuation units. Generally, in such a TS, stainless steel tubes (SS tubes) are used to transmit torsion and translation to the distal nitinol (NiTi) manipulators, and they are angled into a bending unit and extended in parallel. Although.

How a Manual Transmission Works Care My Cars

Power is transmitted through the clutch to the gearbox, passing to the wheels through drive shafts. The layout is similar to some frontwheel-drive cars, except that no allowance need be made for steering movement of the wheels. Sometimes the shafts are connected to the flanges at the gearbox by `doughnut' couplings. Engine Block 18 minutes.

The Manual Transmission Explained All The Basics

Transmission is an important part of powertrain. In the transmission design, in addition to the transmission type, basic performance characteristics and purpose, this chapter mainly introduces the gear design, bearing selection and design, case design, parking mechanism design, synchronizer design, seal selection and transmission ventilation design and transmission test.

Transmission Line Free Stock Photo Public Domain Pictures

The gear tooth matching conditions of the system based on the design characteristics of power flow closed-loop and virtual constraint configuration of the system are established, and the basic parameters of each gear meet the requirements of the system load-sharing layout and synchronous meshing of each branch movement are calculated.